For handling heavy semi-finished products, we have cranes with total load-bearing capacity of 750 kg.

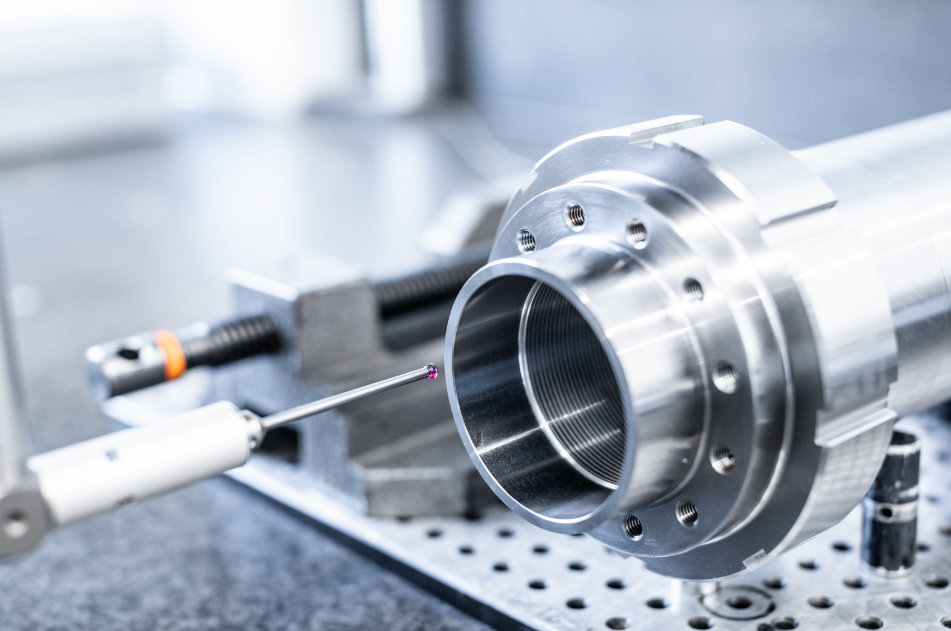

Thanks to the design and performance of the powered tools, it is not a problem for us to comprehensively machine parts with abaxial hole diameters of up to 35 mm and parts requiring the removal of material by means of milling (using blade drills and blade cutters up to 80 mm in diameter).

Thanks to the extremely robust construction of the machines, we focus on milling highly rigid materials (stainless and tempered steel, high-nickel alloys, heavy interrupted cuts).

In the area of cutting tools, we cooperate with the leading global manufacturers Walter, TaeguTec, Seco, Sandvik, Guehring, Ceratizit, Fette and Kennametal.

Technical preparation of production is carried out using the GibbsCAM CAD/CAM system.

ISO Quality Certificate

The Tiger of Czech Business

Project OP LZZ - EDUCA

ACE–TECH s.r.o.

Rybníky V 5681, 760 01 Zlín

info@ace-tech.cz

Czech Republic